Warehousing automation

With the increasing degree of warehousing automation, the requirements for each operation link are also getting higher and higher. For example, the use of forklifts, the original method relies entirely on the recognition and memory of the human eye, which is inevitably full of loopholes. It has become a must-do option to install RFID readers on forklifts to improve identification accuracy and efficiency.

RFID forklifts are mainly used in warehousing, outbound, warehouse moving and stocking.

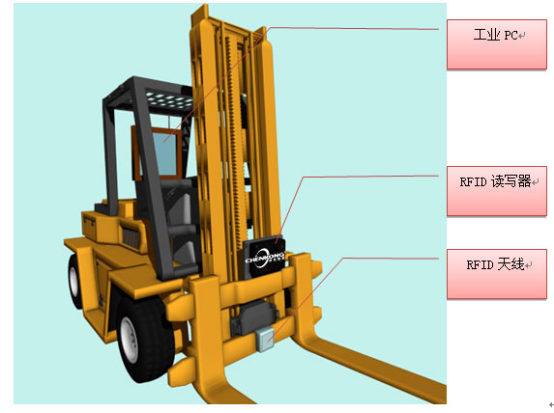

RFID forklift

RFID forklift modification is to install UHF RFID reader, antenna, and industrial terminal on the forklift to realize that the forklift can automatically identify the location information and product information in the warehouse, and the forklift operator can connect with the system in real time on the industrial terminal to improve the warehouse. Management efficiency, reduce the work intensity of operators, and prevent operation errors. Forklifts are changing from a handling tool to an intelligent work terminal. Because the forklift is a special vehicle, there are special requirements for the RFID equipment installed on it. First, the RFID reader is installed at the front end, and the communication with the industrial tablet computer must be wireless; secondly, because the wiring is inconvenient for the power supply of the RFID reader It is necessary to bring its own battery; again because of the particularity of forklift work, the RFID reader, as well as antennas and accessories must be strong and stable enough.

1. Inventory management

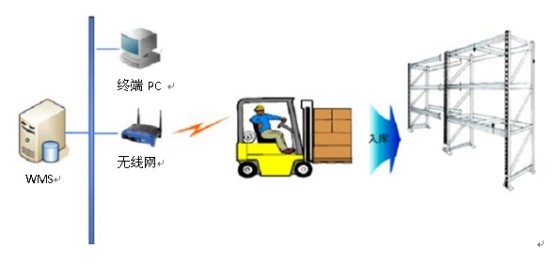

Log in to the system before warehousing. When the forklift picks up the goods, the reader on the forklift purchases the goods information, and the system automatically allocates the location information that needs to be put into the warehouse. The specific process is as follows:

Enter the warehousing system, pick up the goods by the forklift, read the RFID tag information, the system automatically allocates the warehouse location information, the forklift worker finds the corresponding warehouse location according to the allocated warehouse location information, reads the warehouse location label, if the warehouse location information is correct, the on-board computer Prompt that the location information is correct, release the goods, and confirm manually. If the location is wrong, the on-board computer will prompt that the location information is incorrect, and the goods will not be released for the time being. Manual assistance to find the reason.

2. Outbound work

Log in to the system before leaving the warehouse, and the system will prompt the corresponding warehouse location to reduce the time for manual search for the warehouse location. The specific process is as follows:

Enter the outbound system, according to the outbound list, the system will automatically prompt the relevant warehouse location information, according to the warehouse location information, manually find the corresponding warehouse location, RFID reads the goods information and warehouse location information at the same time, picks up the goods, manually confirms, and passes RFID access control , the system automatically collects the goods of the forklift truck and judges whether the goods out of the warehouse are correct. If it is correct, the out of the warehouse is completed.

3. Repository work

When the delivery of a batch of goods is coming to an end and there is not much inventory, or when the next batch of large quantities of goods is received into the warehouse, it is necessary to move the warehouse and move the warehouse.

Through the management system and the forklift terminal, the transfer list is sent to quickly and accurately confirm the shipment content.

4. Stocking operation

According to the customer's order requirements or distribution plan, the products are quickly and accurately picked from their storage positions or other locations, and classified and concentrated in a certain way. Sorting operations generally require that the types and quantities of goods in the order meet certain standards before they are executed.

Hope this article will help you to understand the knowledge of NFC(Near Field Communication)Technology. If you have any more questions feel free to contact me, we are glad to send you our free stock samples for your testing.

Email: info@ayrixtech.com | WhatsApp: +86 15768894185 | Skype: joyrzz

Post time: Sep-02-2022